Overhead cranes, gantry cranes and cranes are essential equipment in many industrial sectors, because of their ability to handle heavy and bulky loads in often difficult environments (factory, loading dock, warehouse…).

A reliable wireless network makes it possible to operate this equipment in real time, ensuring continuous monitoring and optimal management of operations, safely and efficiently. It is a key component in the modernization and optimization of industrial operations.

Lifting and handling equipment is used in a wide variety of applications :

- Handling and transporting heavy materials: manufacturing and production, metallurgy and steelmaking…

- Infrastructure construction and maintenance: civil engineering, oil and gas, mining and quarrying, etc.

- Loading, unloading and transshipment: transport and logistics, power generation…

- Assembly and maintenance in specialized sectors: automotive, aeronautics and aerospace, chemical and pharmaceutical industries…

Integrating a reliable wireless communication network is crucial for :

Safety and accident prevention

A wireless network enables continuous monitoring of equipment, immediately detecting any anomalies or failures. Real-time communication improves coordination between different pieces of equipment and enables corrective action to be taken instantly, reducing the risk of accidents and incidents, and minimizing the risk of collisions or human error.

Operational efficiency

Constant communication optimizes lifting and transport operations, reducing waiting times and bottlenecks, and avoiding unplanned interruptions. Systems can monitor equipment status and anticipate maintenance needs before breakdowns occur (preventive maintenance).

Flexibility and adaptability

A wireless network enables rapid reconfiguration of operations in response to changes in production demands or working conditions. It facilitates the integration of new equipment or extensions without having to install new wired infrastructures.

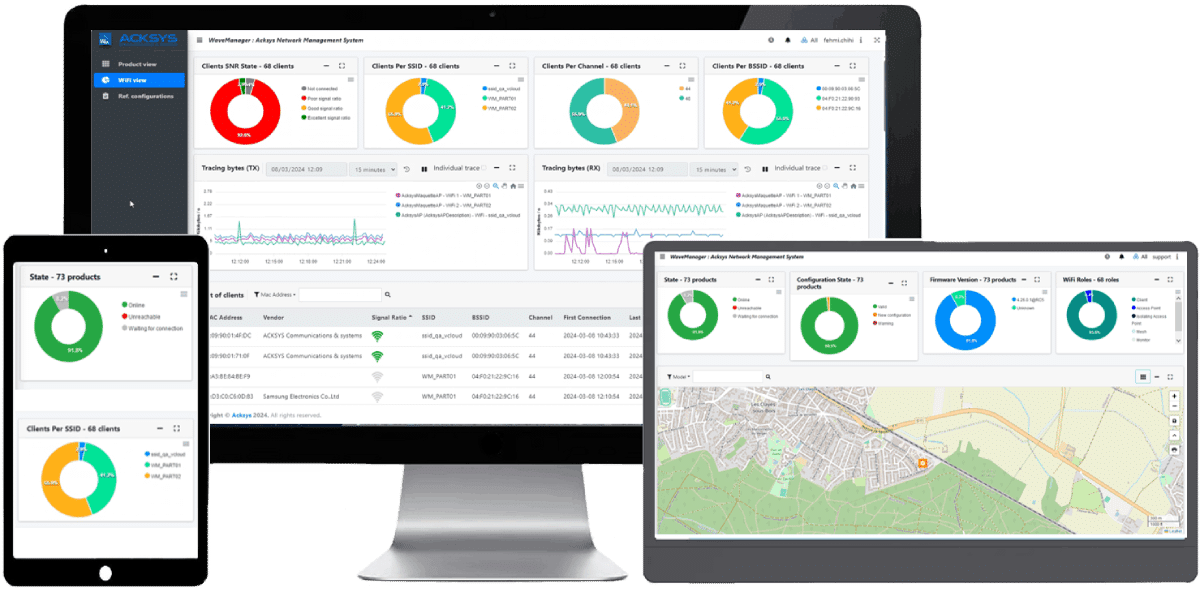

Data collection and analysis

Data collected in real time can be quickly integrated into an ERP or MES system, providing an overview and centralized management of operations. Analysis of this information helps to improve processes, equipment and operator performance, identify inefficiencies and develop continuous improvement strategies.

Cost reduction

With fewer unplanned failures and downtimes thanks to proactive monitoring and maintenance, wireless networks reduce installation and maintenance costs compared to wired networks, while providing greater flexibility.